The manufacturing industry always seeks ways to optimize production processes, reduce costs, and increase efficiency. One of the key factors in achieving these goals is workholding – the act of securing a workpiece in place during machining operations.

Traditional methods of workholding, such as clamps and vises, have been used for decades with varying degrees of success. However, with the rapid advancements in technology and automation, new innovative workholding tools are emerging as game changers in modern manufacturing. In this article, we will explore some of these tools and their benefits.

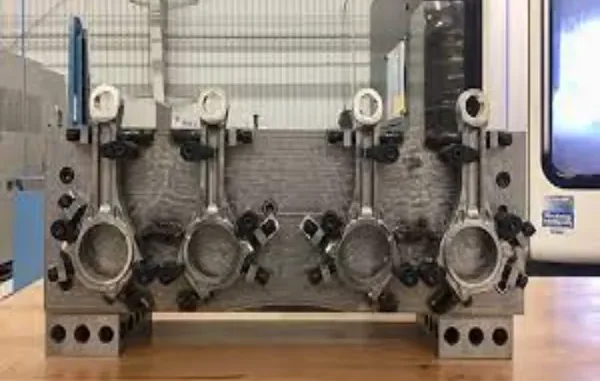

Modular Fixturing Systems

Modular fixturing systems are a versatile and flexible solution for workholding that can be easily adapted to various machining operations. These systems consist of standardized components that can be quickly assembled and disassembled, allowing for faster changeovers between jobs. This reduces downtime and increases productivity, making it an ideal solution for high-mix, low-volume production. Additionally, modular fixturing systems can also be easily reconfigured to accommodate different workpiece sizes and shapes, eliminating the need for costly custom fixtures.

Magnetic Workholding

Magnetic workholding is another innovative solution that eliminates the need for clamps and vises by using powerful magnets to secure the workpiece to the machine table. This method allows for full access to the workpiece, enhancing the ease and speed of machining operations.

Magnetic chucks are particularly beneficial for workpieces with complex shapes or thin walls that are difficult to hold securely using traditional methods. They provide a uniform holding force, which reduces the chances of deformation during the machining process. Furthermore, magnetic workholding setups are quick to configure and release, significantly reducing setup time and increasing overall efficiency in the production cycle.

Vacuum Workholding

Vacuum workholding is yet another innovative solution that uses suction to secure the workpiece in place. This method is particularly useful for flat, non-porous workpieces, such as sheet metal or glass. By creating a vacuum seal between the workpiece and the machine table, this type of workholding ensures stability and accuracy during machining operations.

Vacuum workholding also offers full access to the workpiece, allowing for uninterrupted machining and reducing the risk of interference. This method is highly efficient and has a low setup time, making it ideal for high-volume production.

3D Printing Workholding Solutions

With the rise of additive manufacturing, 3D printing workholding solutions have emerged as a game changer in modern manufacturing. These solutions use 3D printing technology to create custom fixtures and jigs tailored to the specific needs of each workpiece. This allows for a more precise and secure hold, increasing accuracy and reducing scrap during machining operations.

Additionally, 3D printing workholding solutions are cost-effective, as they eliminate the need for expensive tooling or custom fixtures. They also offer the flexibility to quickly adapt to design changes or new workpiece requirements.

Improving Workplace Safety

Apart from increasing efficiency and reducing costs, these innovative workholding tools also have a significant impact on workplace safety. Traditional methods of workholding often require manual handling of heavy and bulky fixtures, which can pose a risk of injury to workers. With the use of modular fixturing systems, magnetic workholding, vacuum workholding, and 3D printing solutions, the need for manual handling is greatly reduced, promoting a safer work environment.

In conclusion, the rapid advancements in technology have led to the development of innovative workholding tools that are revolutionizing modern manufacturing. These solutions offer improved efficiency, increased productivity, and enhanced workplace safety. As technology continues to advance, we can expect even more game-changing developments in workholding that will further optimize production processes and drive the industry forward. So, manufacturing companies must stay updated with these advancements and adopt them to stay ahead in the competitive market.

Leave a Reply